18 Aug What is Torrefaction?

Utilities with investments in existing coal-fired power and CHP plants in Western Europe and North Asia are increasingly looking for solutions to extend operations of their plants in alignment with their governments’ directives to reduce carbon emissions. Some governments have set end-dates for the operation of any coal-fired plants, even though these plants may have many years remaining in their design operational life.

One solution is to introduce torrefied black pellets (also known as ‘bio-coal’) into the fuel-mix in these plants. Torrefaction, a mild form of pyrolysis, converts woody biomass into a carbon-neutral form of energy that can be economically produced, transported and combusted in various energy-intensive industries, including power generation.

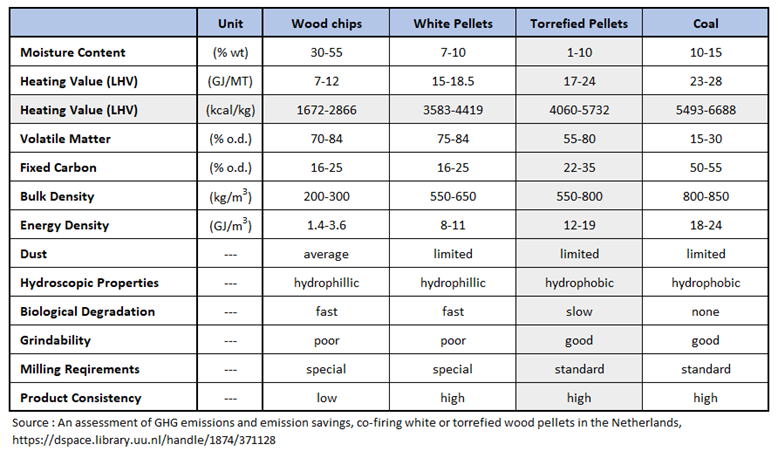

Torrefied black pellets have many of the same physical characteristics as coal: energy density, grindability, hydrophobicity and flame qualities. These characteristics set it apart from the typical ‘white wood pellets’ currently used in many bio-power plants. Torrefied black pellets can be run up to 100% in coal-fired boilers without requiring additional capital expenditures for upgrading storage, feeding, grinding or burner systems in the power plant.

A successful test run of up to 100% of torrefied black pellets at PGE’s Boardman coal-fired plant in Oregon during 2017 demonstrated the potential for use in a coal-fired plant without expensive modifications required Successful Torrefied Biomass Test Burn at a Coal Power Plant (powermag.com)

An example of a successful torrefaction technology is the Dutch company, Yilkins (www.Yilkins.com). A video of their torrefaction process can be seen at Yilkins Torrefaction Process.